| Back to Back Issues Page | |||||||||||||||

|

|||||||||||||||

|

PWL#166, Welding Pipe Downhill, Sinter Brazing, New Brazing Alloys, Prevent Defects in Alum Welding June 01, 2017 |

|||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#166 PWL#166, Manual Shielded Metal Arc Welding (SMAW) of Pipe Downhill, Sinter Brazing by unifying sintering and brazing in the same heat cycle, New Brazing Filler Metal Alloys, summaries of research papers presented at the 11th International Conference on Brazing, How to Prevent Defects in arc welded Aluminum, Laser Shot Peening, Advanced Instrumentation for Putting Welds to the Test, Study to Find the Truth and much more... June 2017 - Practical Welding Letter - Issue No.166DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. 1 - Introduction 2 - Article - Welding Pipe Downhill 3 - How to do it well: Sinter Brazing 4 - Brazing Filler Metal Alloys 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: How to Prevent Defects in arc welded Aluminum 8 - Site Updating: Laser Shot Peening 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Putting Welds to the Test 12 - Testimonials 13 - Correspondence: a Study to Find THE TRUTH 14 - Bulletin Board

2 - Article - Welding Pipe Downhill

The May 2017 issue of the Welding Journal runs at page 90 an interesting article full of practical hints for those welders whose job is to weld pipes. It deals in particular with field welding API 5L line pipe in grades X42 or X52, where many welding procedures, for thin wall pipes 0.5 in. or less, require downhill shielded metal arc welding (SMAW) using covered electrodes of cellulosic type EXX10. The article reminds that this particular electrode cover permits to run "hot and fast" downhill welding with higher productivity relative to alternatives, using direct current electrode positive (DCEP) with higher voltage than required by other electrodes. New inverter power sources are available with special control knobs for optimizing cellulosic operating mode. The article specifies a few setup data required for downhill pipe welding: interested readers should seek the original, because summarizing the recommendations would deprive the exposition of essential information. Criteria are given for the selection of bevel, root opening and electrode size. Tack welds size, position and preparation are recommended. Then specific hints are given for selecting amperage, electrode orientation and drag angle. Further indications are given to manage the "keyhole", essential for assuring complete penetration. Additional explanations and "how-to" instructions are also given to instruct welders on the best way to deposit fill and cap passes. The final recommendation is, quite obviously, to practice as much as needed. The original article is recommended reading for all, and specially for involved new welders.

On a root pass with a properly sized keyhole, very little light appears on the outside of the pipe, as the arc force pushes the weld metal through to reinforce the backside of the joint. [From the Welding Journal May 2017 - page 93] 3 - How to do it well: Sinter Brazing

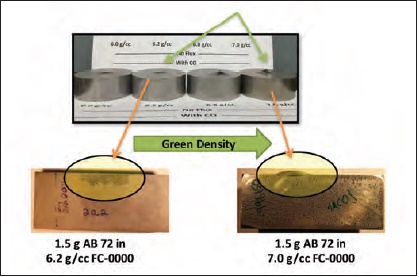

Among the various fabricating techniques used to build components for different industries, the Sinter Brazing process offers an interesting way to produce complex assemblies by unifying sintering and brazing in the same furnace heating cycle. An article on the fundamentals of this process was published at page 44 in the May 2017 issue of the Welding Journal. Success can be assured only if the severe criteria of surface cleanliness from contaminants and suitable clearences are respected. Oxides should be completely reduced before brazing filler metal can flow and wet the surfaces to be joined. An important factor is the required equilibrium dew point at the brazing temperature. Densities of the green preforms must be so compact that porosity will not absorb an eccessive part of the brazing alloy, depriving the joint of the filler. Flux is sometime used to reduce oxides, if found necessary. Interested readers are urged to seek the original article. Experienced readers who may have comments to add are invited to contribute them here.

Lower density powder metal compacts pull more fillermetal from the joint clearance than the higher density compact of the same material. [From the Welding Journal May 2017 - page 46] 4 - Brazing Filler Metal Alloys

The Brazing and Soldering Today supplement, published in the May 2017 issue of the Welding Journal at pages 52-56 provides information on the following items:

A list of 16 bibliographic References to the Sources is reported. In the above pages are reported summaries of research papers presented at the 11th International Conference on Brazing and Diffusion Bonding, held on June 2016 at Aachen, Germany. 5 - Online Press: recent Welding related Articles German Research Institute Uses VSHAPER ONE Pro 3D Printer to Study and Analyze Metal-Polymer Hybrid Structures Impact of Arc Welding Technology on Consumption of Welding Consumables SABIC and Airborne Join Forces to Develop Automated Composites Processes Welding Dissimilar Metals for New Product Designs Cyan Tec to deliver laser welding system to Nuclear Advanced Manufacturing Research Centre 6 - Terms and Definitions Reminder Abrasive Waterjet Machining is a cutting process using a high speed water jet with or without abrasive particles to produce cuts into solid metals, ceramic, glass and composite materials. Brittleness is the tendency of a material to fracture without prior noticeable plastic deformation. A brittle fracture may be not an intrinsic property, but due to stressing conditions (i. e. low temperature). Cavitation is the formation of vapour cavities in a liquid that are the consequence of forces acting upon the liquid. Dew point is the temperature to which air must be cooled to become saturated with water vapor. Eddy-current testing is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials. Faying Surface is one of the mating surfaces that are in contact at a joint. Gas welding is a nonstandard term for oxy-fuel gas welding. Heat affected zone crack is a crack occurring in the heat affected zone. 7 - Article: How to Prevent Defects in Arc welded Aluminum

Confronted with more severe requirements in nondestructive radiographic and ultrasonic testing of aluminum welded structures, a shipbuilder had to eliminate all sources of unwanted hydrogen that could have found their way in aluminum weldments, producing unacceptable porosity. Systematic searching for the causes of inferior quality and for the needed improvements brought about a check list of items and of recommendations, then organized in an article published in the May 2017 issue of the Welding Journal at page 96. Detailed warnings were formulated and supplied to all welders involved, to avoid all contaminants. Besides eliminating moisture, water and lubricants, instruction were given to use only electric tools, because the exhausts of pneumatic ones may contain moisture or lubricants and contaminate joints to be welded. Coiled filler metals must be kept in their original package, to be removed only when used. Moisture should not be permitted to condense on cool wire surfaces. Welding equipment with plastic liners must be dedicated to aluminum only to avoid contamination. Shielding gas must be dry, of suitable flow and dew point. A few more recommendations are spelled out. A table describing possible causes of porosity is included in the article for guidance. Finally a list of good practices explains how to perform grinding for exposing incomplete penetration. Attention to the highlighted details should improve performance to acceptable non destructive test results. Interested readers are urged to seek the original article summarized here.

Mechanized GMAW of an aluminum aircraft elevator for the USS Gerald R. Ford. [From the Welding Journal May 2017 - page 96] 8 - Site Updating: Laser Shot Peening

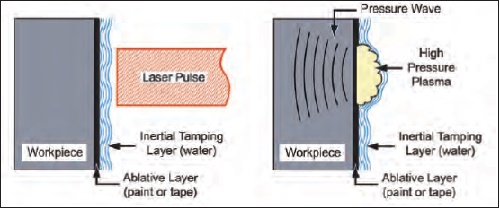

Following the suggestion of an article published at page 38 in the May 2017 issue of the Welding Journal, a revised section summarizing the characteristics and the benefits of the process mentioned in the title above, was merged into the page on Shot Peening appearing since a long time in our website. The article above traces a short history of the development of laser shot peening, which lasted for some decades, starting around 1960 with the development of the first pulsed lasers. By pulsing laser beams on the surface of materials suitably protected, high pressure plasma is generated, inducing layers of residual compressive stresses deeper than standard shot peening (which shoots hard particles made of metal, glass, or ceramic at the surface of the material undergoing treatment). The presence of compressive stresses has the remarkable effects of resisting cyclic loading that produces fatigue failures, and also of slowing down crack growth. The article reviews the behavior of different materials treated by laser shot peening and reports some of the published results of research: it remarks that additional testing is required to complete a better understanding of the benefits to be gained by LSP. Selected sensitive parts of aircraft engines and generally high-cost and high-importance applications are currently processed by this technique because of their documented longer fatigue life in regular operation. But, the article concludes, the ability to reliably increase the strength of weldments by inducing compressive stresses can benefit in the future the entire welding industry. The above website page can be found at www.welding-advisers.com/Shot-peening.html Readers are urged to send us comments and feedback, or original contributions originating from experience and practice with welding related techniques using the Contact Us Form.

LSP drawing detailing the laser pulse, opaque and transparent layers, and plasma cloud. [From the Welding Journal May 2017 - page 39] 9 - Short Items

9.1 - Salt Bath Heat Treatment for metals is carried out in a bath of molten salt. 9.2 - Tempering, in heat treatment, means reheating hardened steel or hardened cast iron to some temperature below the eutectoid temperature, for the purpose of decreasing hardness and increasing toughness. The process also is sometimes applied to normalized steel. 9.3 - Ultimate Elongation of a tensile specimen is the elongation measured at rupture. 9.4 - Vacancy is a structural imperfection in which an individual atom site is temporarily unoccupied. 9.5 - Water Quenching is a quench in which water is the quenching medium. The major disadvantage of water quenching is its poor efficiency at the beginning or hot stage of the quenching process. 9.6 - X-ray Spectrometry is the measurement of wavelengths of x-rays by observing their diffraction by crystals of known lattice spacing.

10 - Explorations: beyond the Welder The Human Nose Knows More Than We Think Climate Change Is Turning Antarctica Green What Are Software Vulnerabilities, and Why Are There So Many of Them? Trump Budget Would Slash Science Programs across Government Bizarre Star Dims Again, and Astronomers Scramble to Catch It in the Act 11 - Contributions: Putting Welds to the Test

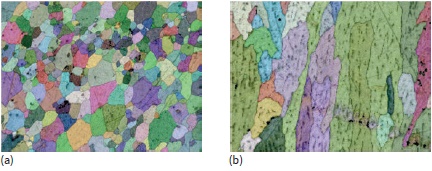

An article under the above title was published at page 30 in the April 2017 issue of Advanced Materials and Processes (AM&P), a publication of ASM International. In the interview, the editor asked the product manager of a manufacturer of advanced instrumentation, what can be done to alert welded components builders of impending failures causes hidden in the products they make. The first answer was that industry as a whole is investing heavily in developing analytical instrumentation technology and test procedures that more directly and reliably expose root causes of failures. In the case of metal welds, manufacturers now have access to powerful imaging techniques such as electron backscatter diffraction (EBSD), meaning they just need to put a weld sample under a scanning electron microscope and look for telltale microstructural changes. To make advanced weld testing more accessible to the industry one needs improved cooperation between academy and industry to teach the latter how to profit from the use of modern analytical tools and how to implement best practices for weld test procedures. Efforts are being done in this direction and productive cooperation is bound to reach tangible results. Interested readers are invited to seek the original article that can put them in contact with the scientist of the instrument producer, possibly capable to address them to the solution of problems they may have.

EBSD Euler maps reveal microstructural changes in aluminum caused by welding. [From AM&P April 2017 - page 30] 12 - Testimonials On Wed May 10 14:19:40 2017, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Jim Warren 13 - Correspondence: a few Comments As our attentive readers may know, we have been using for quite a long time a friendly tool to build and expand our website (www.welding-advisers.com). The friendly tool is called Site Build It (SBI for short) and it provides all services that a person should use to build an attractive website to inform, entertain and satisfy readers on the particular topic (niche) selected. This is particularly important to anyone having no previous computer or website experience, but it is much more than that. We add generally a few links for interested readers to easily access this very rich source of instruction and encouragement, which includes lessons on how to do it. Many examples are available, concerning successful entrepreneurs who reached their goals by building a business of exploiting their particular interest. Site Build It is proud of the success enjoyed by the persons it helped to overcome all sorts of difficulties on the way to a rewarding life of satisfactory achievements. Lately though they got notice of an unscrupulous competitor who entices its followers to steer away from SBI by promising success along a faulty route to nowhere. It appears that a company called Wealthy Affiliate ("WA") has been misleading folks who search for reviews about Solo Build It!. Its affiliates post "fake reviews" that rank high at Google. The affiliates mislead people into believing they're reading a review (i.e., a fair and balanced review, followed by a recommendation). They have actually entered a sales funnel for WA -- whatever the content may be (usually some rehash of inaccurate material), affiliates recommend WA as #1. SBI reaction was to Conduct a Study to Find THE TRUTH. Link to Part 1 of the Study: Intro & Summary: Fake Reviews vs. A Peek at the Truth: Link to Part 2 of The Study: Objective, Rigorous, Statistically Significant, and Reproducible: Link to Part 3 of the Study: The Results: Even a cursory review of the Study easily reveals that the purpose of Wealthy Affiliate is to induce readers to believe in fake revues, to embark in the useless exercise of writing more of the same, and to recommend WA without any proven reference of their claimed "best" status, in preference to SBI, despite their solid demonstrations on the effectiveness of their philosophy and longtime history of honest deeds. We urge our readers to keep clear of WA and, if they want to explore how to build a honest business by investing their time and mind in building a successful internet business, to trust SBI as a faithful hand ready and willing to help them out. PWL 14 - Bulletin Board 14.1 - National Robotic Arc Welding Conference and Exhibition. 14.2 - Additive Manufacturing with Powder Metallurgy. 14.3 - 70th IIW Annual

Assembly and International Conference.

See you next time...  Watch - The Video: and also BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell? Copyright (©) 2017, by Elia E. Levi and Back to Past Issues of PWL. | |||||||||||||||

| Back to Back Issues Page |