| Back to Back Issues Page | |

|

|

|

PWL#050 - Ultrasonic Consolidation, Weld crack Repair, Filler Metal for HSS, Hot Wire TIG, Weld Art October 01, 2007 |

|

| We hope you will find this Letter interesting and useful. Let us know what you think of it. PWL#050 - Ultrasonic Consolidation, Weld Crack Repair in a Transition Part, Filler Metal for welding High Strength Steels, Hot-Wire TIG, Welding Art new Page, More on TRIP Steels and more...

This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. We actively seek feedback to make it ever more useful and up to date. We encourage you to comment and to contribute your experience, if you think it may be useful to your fellow readers. You are urged to pass-along this publication to your friends, if you like it, and if you want to help them. If you received this from a friend and if you like what you read, please subscribe free of charge and you will also receive a bonus book on Practical HARDNESS TESTING Made Simple.

1 - Introduction 2 - Article: Aircraft Damage Repair Project 3 - How to do it well: Repairing a Crack in a weld 4 - Filler Metal for joining High Strength Steels 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article - Hot Wire TIG 8 - Site Updating: Welding Art 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contribution: More on TRIP Steels 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

1 - Introduction Time for Celebration! Almost without realizing it we are now at the 50th Issue of PWL! Thanks to those of our faithful Readers who expressed their appreciation for our efforts, we feel that our toil is likely to have benefited some of them, one of whom asked recently how could he get some of the oldest PWL issues! This is one of the most coveted awards I could hope for, and it comes at the right time. Announcement I am pressing on with some new projects I will propose shortly to my readers. I am confident that this initiative will meet with your interest and approval. Given the amount of time and effort that I am spending in preparing the material, I will have to charge a nominal sum for every copy of it, but the neat return to the Readers who will buy it, will repay them many times of the modest investment required. Invitation I am just waiting for the permission to reprint a short note that will open the new page on Welding Talk. It is on the application of a specific product that may be useful to many Readers. If you are shy of being the first on this page you should not, because the above note is scheduled to be Number 1. Anyhow we would be delighted to have in this page your comments on the best value you found in this website, or your notes on how our information or a direct answer solved a problem for you, or again which kind of explanations in PWL is most useful for you. So, you are welcome to click on the above page and start typing directly in the Form. In this PWL Issue We open with the announcement of a new project just started on Ultrasonic Consolidation, that in our view is going to open up a new way not only for repairing damaged parts but for making new parts with advanced composite materials. If the project meets its goals we will be hearing of it more and more in the future. Just stay tuned. The next section gives an example on how NOT to ask a question. A misleading question returns a useless answer. High Strength Steels are important construction materials. Filler Metal for welding them in useful constructions comes in many types. A guide, helping in selecting the best for an application, may be just what you need. We give the reference to a fundamental article clarifying the main issues. Hot-wire TIG is a high deposition rate modification of a well known process. You may wish to explore if it could give a push to your project. A Gallery for showing the Artworks of endowed welders, is our new Welding Art Page of this Month. Readers are invited to ask the Artists they know to send us photos of their creations with a short story attached. If you are an Artist, we invite you to send us from that page a photo of an exemplary Creation of yours, together with a short story on what is going on behind the scenes of your Artwork. You will gain a link and some exposure. TRIP Steels find their place in automotive body construction. A few references are offered to gain increased understanding on their useful properties. That is about what you are going to find in this Celebration Issue, besides the regular sections at their usual places. A special request is included in our Bulletin Board for the few of you who may have an answer. Let us know. 2 - Article: Aircraft Damage Repair Project We reported recently on Issue No. 043 of Practical Welding Letter for March 2007 (2) on Laser Fused Material Deposition technology used for reclaiming expensive worn and scrapped parts made primarily of titanium Alloys. Click on PWL#043 to see the article. Now we learn from a news release (http://www.solidica.com/newsArticles/Solidica_PR%20NCMS%20Titanium_FINAL_2007-05-18.pdf) of a new project initiated to develop a different process, namely solid state Ultrasonic Welding, (or Ultrasonic Consolidation as it was dubbed) to repair damaged titanium parts. While the first process was mainly intended to deal with engine components (e.g. fan blades and compressor parts) the new one is possibly meant for airframe elements. The Company selected as the leader for the new project has previous experience with Ultrasonic Consolidation and shows in its website a machine capable of building by ultrasonic welding, layer by layer, complex prototype parts from a drawing. See It is amazing to think of the possibilities opened by this technology, that permits in principle to embed integrally in any part different materials as needed or layers of metal sheets strengthened by fibers or by particles (MMC Metal Matrix Composites). When the process is suitably developed and Designers become familiar with it, unthinkable parts with unheard of properties will be commonplace, and many manufacturing problems will be solved by this technology. 3 - How to do it well: Repairing a Crack in a weld Q: Al 5356 vs SS 304: would you help me to find the proper filler metal for welding together these two materials? A: The answer to this question is straightforward: Unfortunately the two materials are incompatible, that is they cannot be fusion welded together. Please see my article: Joining Incompatible Materials

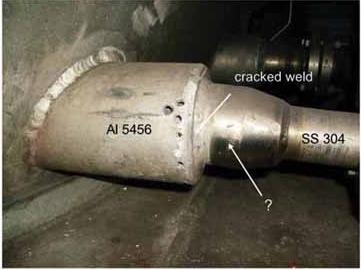

But it appears that the question was not formulated correctly. Correct Q: "This is a photo of the joint we are talking about. The equipment is a nitrogen tank carrier. I need to repair the cracked weld. Would the reduction pipe be a transition material between Aluminum and Stainless?" A: Yes. The reduction pipe is a transition part obtained made by friction welding together an aluminum and a stainless elements. The aluminum side of the transition element was later arc welded to the aluminum construction, while the stainless part was welded to the stainless tube. As the crack appears to be wholly confined to the aluminum joint, it should be dealt with like a repair in an aluminum part. Conclusion: A misleading question may produce a useless answer.

The Question Mark points at the location of the Friction Welded Joint of the Transition Part, connecting an aluminum element to a stainless cone. 4 - Filler Metal for joining High Strength Steels To anyone involved in selecting filler metal for welding High Strength Steels we recommend to study the article published in the Welding Journal of July 2007 at page 26. The underlying assumption is that a proper selection permits to achieve the required mechanical properties while eliminating the need for costly additional heating provisions. The many factors to consider in selecting a GTAW or FCAW electrode for a given application are highlighted and explained. First in the list is the chemical compatibility of the filler with the base metal and the electrode weldability to produce crack free welds, by suitable resistance to hydrogen-assisted cracking (HAC) in weld metal and heat affected zone (HAZ). Mechanical properties are governed by microstructure which depends on chemical composition and thermal processing. It is customary to check the response to heat treatment of steel and of weld metal by examining the Carbon Equivalent Number (CEN), a synthetic number calculated by one of the accepted formulas which take into account a weighted contribution of the different elements. The article suggests to limit the acceptable carbon of the electrode to less than that of the base metal and to establish 0.12C weight % as the upper limit. Achieving acceptable strength and impact properties is one of the main tasks of proper selection, keeping into account the need to limit weld energy because of its adverse effects on mechanical properties. The article provides equations for determining critical transformation points based on chemical composition, with the objective of selecting an electrode of suitable CEN while achieving a substantial lowering of transformation temperatures relative to those of the high strength steel base material to be welded, to permit the formation of favorable microstructures. The article further stresses the limitations of current electrode specifications which do not distinguish among essentially different electrodes although they may all meet specified criteria, and also do not stress the fact that certain selections may involve special welding procedures having influence on costs and delivery schedules. Interested readers are urged to seek the original article indicated above.

5 - Online Press: recent Welding related Articles Choosing Shielding Gases for Arc Welding From Miller Electric: Friction Stir Welding for Ship Construction From TWI: The complete Issue 4 - July 2007 (in pdf format) of 6 - Terms and Definitions Reminder Adhesive Bonding is a process for joining materials whereby an Adhesive is placed between the faying surfaces. Upon curing the adhesive solidifies to produce an adhesive bond. Complete Fusion occurs over the whole base metal surfaces to be welded and between all adjoining weld beads. Constricting Nozzle is a device at the exit end of a plasma-arc torch or plasma spraying gun that contains the constricting orifice through which the arc plasma is made to pass. Longitudinal Weld Test Specimen is a tensile test specimen with a weld parallel to the specimen axis, roughly along its longitudinal center line. Moving Shoe is a backing shoe that slides along the joint during welding. Paste Solder is a mixture of finely divided solder particles with flux or neutral carrier. Substrate is the material onto which a thermal spray or other deposit is laid. Transverse Weld Test Specimen is a tensile test specimen with a weld perpendicular to the specimen axis, roughly at mid length. 7 - Article - Hot Wire TIG A first note on this process was published in the Short Items section (9) of Issue 04 of Practical Welding Letter for December 2003, quite a long time ago... It is well known that GTAW (Gas Tungsten Arc Welding or TIG = Tungsten Inert Gas) permits to perform high quality welds, like root welds in demanding tubing applications. In the manual process filler metal can be provided by the welder as needed. For mechanized applications an additional feeder can supply from the side of the torch, weld (cold) wire to be melted in the heat of the arc, much as was done manually, but with increased speed and regularity. The wire is pulled from a reel through motorized pairs of rollers driven at a suitable adjustable speed. Nonetheless the weld deposition rate remains well below that of GMAW (Gas Metal Arc Weld or MIG = Metal Inert Gas). The Hot Wire Tig process was introduced to increase the deposition rate while maintaining the TIG advantages like better control of heat input, because the wire speed is now independent from the arc current. This process is therefore well suited to surfacing work as it permits to bring down dilution to a minimum, and it also improves side wall fusion, a well known problem with deep groove welds. The hot wire process is obtained by adding to the wire feeder a special power source that heats the wire by resistance heating to the flow of electric current between a contact point in the adapted torch and the work. The heated wire, enclosed in a shielding gas, is melted when it enters the molten weld pool. The heat input in the wire depends on the current flowing and on the free wire length (about 20 to 25 mm) between the sliding contact and the work. Voltage in this circuit is kept low, between 2 and 10 Volts, to avoid arcing. High conductivity materials like aluminum and copper do not lend themselves to the application of this process. The process is well suited to carbon and alloy steels, stainless steel and nickel alloys. The parameters governing the hot wire control are totally independent from those that control the arc, thus providing freedom in the search of the best procedure for the application at hand. One can find power supplies with AC or DC, continuous or pulsed at variable, selectable frequency. Arc blow should be controlled as needed. The angles of the feeding wire to the work and to the electrode can be established independently, as well as the exact position at which the wire enters the molten pool, relative to the location of the tungsten electrode. All these parameters have influence on the outcome, that, we remind, should result in high quality welds at a high weld deposition rate. The advantages of Hot Wire Tig should be explored when the application looks promising for the benefits that can be gained. 8 - Site Updating: Welding Art The Page of this Month was for a long time in our mind as a project but other more pressing duties caused this excessive delay. A first hint was published here in December 2003 (PWL#004). At last it is now online, and with it an Invitation to all Welders Artists who wish to display their Artwork, in the page (or accessible from the page) to fill in a simple form and join in. Our hope is that the page will grow in time, by initiative of the Artists themselves, to represent a selected Gallery of current Creations and a reference meeting place for all interested Readers. To reach the new page click on Welding Art and to accept our Invitation fill in the Form there and send us the Contribution of your own Artwork. The non-artist Readers are invited to send their stories, notes, comments, ideas, feedback, recommendations or funny remarks to our other Page dedicated to Welding Talk. Would you think that there should be a place, in this website, for Welding Exchange, where readers might look for or offer surplus equipment? Let us know your thoughts on this subject. Write us a note by e-mail. Click on Contact Us. A usual we recommend that you look periodically at our Site Map and that you frequently keep an eye on our Blog. 9 - Short Items Continuous Casting is a technique whereby a cast shape is continuously withdrawn as it solidifies through the open bottom of a cooled mold, so that its third dimension is not determined by mold size. Used to produce semifinished mill products such as billets, blooms, ingots, slabs, strip, and tubes. Holding Time, in heat treatment, is that for which the temperature of the furnace and of the heat treated metal object is kept constant for allowing temperature equalization or time dependent transformations. Malleability is the characteristic of ductile metals that permits forging or plastic deformation in compression without fracture. Pack Carburizing is an obsolete method of surface carbon enrichment of steel in which parts are packed in a steel box with a carburizing compound and heated to elevated temperatures until they gain surface carbon through diffusion. They are then cooled slowly, removed from the spent compound and got ready for further hardening through heating and quenching. Proportional Limit is the maximum stress a material is capable of developing in a tensile test without deviating from straight-line proportionality between stress and strain. Shim is a thin piece of material foil used between two surfaces of an assembly to obtain proper fit, adjustment, or alignment.

10 - Explorations: beyond the Welder The Vision for Space Exploration The Texts of Masterpieces Photobook Kids Games SBI! Builds Sites That Work 11 - Contribution: More on TRIP Steels TRIP steels were briefly introduced as a Short Item in a previous issue of Practical Welding Letter. Click on PWL#027 to see it in 9.6. See the following articles for an overview of this important class of steels: http://www.key-to-steel.com/default.aspx?ID=CheckArticle&NM=194 http://www.thefabricator.com/MetalsMaterials/MetalsMaterials_Article.cfm?ID=1139

12 - Testimonials To: Welding Advisers That is an excellent idea as we will be building more of this product in the near future. I appreciate your quick response. I also am enjoying your newsletter. Very informative. Best regards, Paul Ipolito

To see the following Testimonial (needs Adobe Acrobat installed), click on

13 - Correspondence: a few Comments 13.1 - I already pointed out above in this page that faulty questions cannot but produce meaningless answers. Inquirers are urged to provide as much information as needed to describe their real problem. 13.2 - Sometimes a picture is worth a thousand words. I receive long descriptions of assemblies I cannot understand. A simple sketch would clarify all issues. The only problem may be the memory size of my Inbox. I would provide to readers asking for it my alternative email address with a larger Inbox, for sending me sketches, drawings or photos. 13.3 - Did my answer help you? Be so kind to let me know. You are invited again to send your comments through the Welding Talk page, using that form, thanks. 14 - Bulletin Board 14.1 - Special Request: A Company is seriously interested in finding a manufacturer of mobile equipment for electroslag welding. Required previous experience with field welding of tyres (rotating tracks) for rotary kilns employed in cement manufacturing. If you think you may know where we should be looking for, please let us know your suggestions. Click on Contact Us for sending us your message. 14.2 - Cold Spray 2007 14.3 - Surface Hardening of Stainless Steel 14.4 - International Conference and Exhibition

POWERED BY: Click on this Logo NOW! Copyright (©) 2007, by Elia E. Levi and See you next time... |

|

| Back to Back Issues Page |