| Back to Back Issues Page | |||||||||||||

|

|||||||||||||

|

PWL#135 Learning f/Exper,Unclean Brazing, Metal cored galvanized, Acoustic Sectioning, Activated TIG November 03, 2014 |

|||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#135 Learning from Experience, Vacuum Brazing in an uncleaned Furnace, Metal Cored wire for welding galvanized steel, Nondestructive Acoustic Cross-Sectioning , Activated TIG Welding, Welding Applications, Bulletin_101 Resources on Welding Productivity and much more...

November 2014 - Practical Welding Letter - Issue No.135

Important NoticeThe Mid October 2014 Issue of Practical Welding Letter, Bulletin 101, introducing online Resources on Welding Productivity was not distributed by e-mail but is available at Bulletin 101 and from the Welding Resources Page. DON'T USE REPLY to send your messages! Use the Contact Us form

instead. This publication brings to the readers practical answers to welding problems in an

informal setting designed to be helpful and informative. We actively seek feedback to

make it ever more useful and up to date. We encourage you to comment and to

contribute your experience, if you think it may be useful to your fellow

readers. You are urged to pass-along this publication to your friends, if you like it,

and if you think it may help them. If you received this from a friend and if you like

what you read, please Subscribe free of charge and you will also receive a bonus book

on Practical HARDNESS TESTING Made Simple. The addresses reported hereafter were live and correct at the time of their

publication. There is no guarantee that they will always be so, because they are

administered by the sources themselves and are under their control. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". These are not live and must be copied and pasted entirely into the browser (after having been selected with the mouse or otherwise). If they are long they may be displayed in two or more lines. In that case one has to care that the URL be copied completely in a single line without any space, and Enter. If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. You are welcome to forward this page to those of your friends who may profit of this information.

(Sponsored Links)

1 - Introduction 2 - Article - Learning from Experience 3 - How to do it well: Brazing in an uncleaned vacuum furnace 4 - Filler Metal Cored wire for welding galvanized steel 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Nondestructive Acoustic Cross-Sectioning 8 - Site Updating: Welding Applications NEW, Bulletin_101 NEW 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Activated TIG Welding 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Learning from Experience I believe that much can be learned from experience, even from errors.

Some time ago I got a message from a longtime friend, whom I thank for

his kind consideration that such a subjet might be of interest to our readers.

This episode from real life should teach every welder and supervisor that Welding Procedure Specifications (WPS), for assuring reliable quality, are useful only when they are applied fully and conscientiously. Such mistakes are obviously costly in terms of materials and of time lost. The costs however could be even more expensive if the customer confidence is shaken. Readers are invited to check if in their own environment similar mishaps could happen, and what would they do to reduce or eliminate this unfortunate chance.

View the following:

3 - How to do it well: Brazing in an unclean vacuum furnace

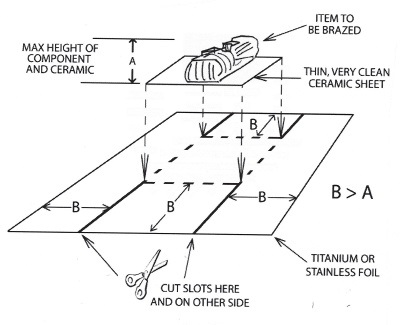

The article published in the October 2014 issue of the Welding Journal at page 34 answers to the question of how to handle an urgent brazing job for a pressed customer, immediately after another job left the vacuum furnace contaminated. There is no time to run a regular maintenance, including hand cleaning, vacuuming and leak testing, and high temperature burn out cycle. It should be avoided using the furnace as is, as it risks to produce contaminated welds especially in stainless steels or titanium. The article suggests to build a simple box of stainless or titanium foil, kept for this purpose in rolls, ready for this kind of one time use. The box is made by hand, using clean gloves and clean simple tools for bending and crimping the foil. The foil is laid on a surface and folded up the sides, after making short slits or just folding excess material. A clean thin alumina ceramic sheet is placed on the box base to hold the item to be brazed without any contact with the metal foil. A loose cover made of folded foil is placed on top before starting the brazing cycle. The foil of the box serves as a getter for the outgas products generated in the outer chamber. The custom box is discarded after one time use. Interested readers are invited to seek the original article referred to above.

Fig.1 - Making the base of the foil box to hold components for brazing. From Brazing Q&A by Dan Kay AWS Welding Journal - October 2014 - page 34

4 - Filler Metal Cored wire for welding galvanized steel

An article published in the October 2014 issue of the Welding Journal at page 44 describes the advantages of using a special metal cored welding wire for welding thin galvanized steel to make light automotive vehicle parts. Used with a pulsed gas metal arc welding (GMAW-P) process, metal cored wire carries higher current densities (at equivalent amperage settings) than solid wire, providing faster travel speeds,(40 in./min in robotic applications compared to 23 or 25 in./min for solid wire) which lowers the heat input. Recent advancements in metal cored wires, specifically some carrying the AWS classification E70C-GS, provide significant advantages for welding galvanized steel. These wires feature formulations that allow them to weld with direct current electrode negative (DCEN) polarity. Benefits while operating in DCEN when welding thin-gauge galvanized steel include a softer arc penetration that prevents melt-through on thin-gauged material, wide bead and sufficient arc energy to vaporize the galvanized zinc coating, minimizing surface and subsurface porosity. The formulation not only results in higher deposition rates, but also in good root opening bridging capabilities and a high strength deposit that maintains ductility and impact toughness. The process should be controlled to keep porosity within the limits established by the AWS D8.8M:2007, Specification for Automotive Weld Quality Arc Welding of Steel. The article concludes that, for the specific applications described, the use of the suggested cored wire designed for use with galvanized steel provides increased productivity and improves quality. Interested readers are urged to seek the original article.

Pairing a GMAW-P process with metal-cored wires designed for galvanized steel can help combat many challenges and issues associated with welding the material.

5 - Online Press: recent Welding related Articles Upward spiral

Nuclear supplier agrees to changes after workers accused of cheating on welding test

Orion EFT-1 mission enters pad flow milestones

MagneGas to Demonstrate at the Largest

Fabrication and Welding Event in North America

Getting the fumes out

NSRP project aims to reduce weld distortion

6 - Terms and Definitions Reminder Overexposure to welding fumes is an occupational hazard for welders operating in confined spaces. Specific measures must be adopted for adequate prevention. Penetration Enhancing Flux is a material, applied to the base metal surface, adjacent to the weld joint prior to gas tungsten arc welding (GTAW), that results in increased weld penetration. See Section 11 further down this page. Resistance Stud Welding is a variation of the resistance projection process. Special studs are used with precision embedded projections. Stored Energy Welding is a resistance welding process variation in which electrical energy is accumulated by various means at a slow rate, and then released immediately for welding. Temper time in resistance welding is the one, following quench time, during which a current is flown in the circuit to heat the weld to tempering temperature. Vacuum Heat Treating is performed in an evacuated furnace below atmospheric pressure. Weld Metal Zone is the portion of the weld area observed in a cross section consisting in weld metal.

7 - Article: Nondestructive Acoustic Cross-Sectioning

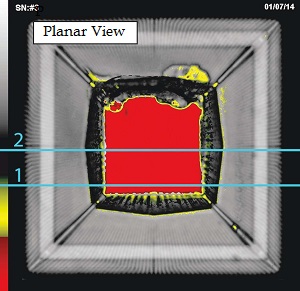

Although physical sectioning of manufactured items is done routinely to calibrate non destructive testing and to obtain proofs helping to improve processes, there is great interest in perfecting methods that do not destroy the examined items. The best known method of nondestructive sectioning is that based on Radiographic Computerized Tomography (CT) widely applied also for human scans. Of the various nondestructive techniques, ultrasonic examination has unique properties that make it useful to detect internal defects, especially planar discontinuities at interfaces where connections should be expected. Industrial applications of the basic methods, build on advances in equipment and software, strive to produce readily interpretable test results, possibly automatic, without inspector intervention. An Article published in the October 2014 issue of Advanced Materials and Processes (AM&P), an ASM International publication, at page 25, reviews recent developments in Nondestructive Acoustic Cross-Sectioning, helping to pinpoint fabrication failures in complex instruments. Different methods, known in the industry as Q-BAM or C-SAM, are applicable providing comparative results that can be adapted to various applications. The first provides linear scans along a line preselected by the operator. The echoes from internal features are detected for each layer separately and recorded. The process is repeated for different virtual layers of the body examined, until the whole volume is covered. The highest degree of reflection is that occurring at solid-to-gap interfaces, like crack or delamination. The display of reflections indicating gaps is typically shown with a high contrast color to make them stand out. Acoustic sectioning permits to establish with great accuracy the precise location of internal features for a physical section that will assure the maximum information relative to the internal details of electronics component or medical package seals or whatever. The representation can suggest to perform a series of acoustic sections along parallel surface lines to produce a slide show of internal features, including defects. Interested readers are invited to read the original article indicated above and, if necessary, to contact the author for more details.

Planar acoustic image looking down into a plastic encapsulated integrated circuit. The two lines indicate the locations for cross-sectioning. From ASM AM&P - October 2014 - page 26

8 - Site Updating: Welding Applications (NEW), Bulletin_101 (NEW) The Pages of this Month deal with different aspects of welding industrial constructions, (as opposed to welded artwork). For best results and adequate performance, one needs quite a large baggage of knowledge, and thorough attention to details. Furthermore it is most advisable to remain updated in welding advancements, to be ready to check if new developments reaching the news, might provide tangible benefits not to be neglected. The first page reminds that the use of specific welding processes to perform a given job is highly conditioned by the materials involved, so that the first selection is limited by compatibility. There are always many acceptable different ways to perform welding for translating drawings in physical structures. Each shop may do that at a certain minimum cost, depending on the influence of specific factors on each element of the total sum. Existing assets like equipment and skilled workforce should be investigated first, to see at what costs their use might provide the required performance. Each shop should obviously strive to minimize those internal costs to maximize benefits. Then, if a certain minimum volume of business can be assured, it may be vital to study if new solutions for automatic or robotic implementation, to be achieved by leasing or purchasing equipment, would assure economic benefits. See this new page by clicking on the link for the Welding Applications page. The other published bulletin provides links to online resources on the subject of Welding Productivity. It is highly recommended to improve productivity by all available means. This endeavor is achieved by first calculating the real cost sustained by the shop for the given job. Possible improvements by other means should then be compared with the computed baseline. See this page of Resources on Welding Productivity by clicking on the link to the Mid October 2014 PWL#134B designated as Bulletin 101. Readers are invited to explore at no cost the welding knowledge exposed in this website. The Site Map may be a good place to start from, for finding critical information. You can always research your topic by typing your relevant terms in the search window appearing in almost all of the website pages. You can also Contact Us if you feel that we could offer some help.

9 - Short Items

9.1 - Carbon Potential is a measure of the ability of an environment containing active carbon to alter or maintain, under prescribed conditions, the carbon level of a steel present, depending on such factors as temperature, time, and steel composition.

9.2 - Dichromate Treatment is a chromate protective conversion coating produced on magnesium alloys in a boiling solution of sodium dichromate (Allodine). 9.3 - Electrolytic Cleaning is the process of removing soil, scale, or corrosion products from a metal surface by making it an electrode (that is by connecting it to an electric current) in an electrolytic bath. 9.4 - Forced-Air Quench is obtained by blasts of compressed air to reduce severity, relative to the use of a cooling liquid. 9.5 - Grain Size Distribution measures by microscopy the characteristic grain or crystallite dimensions in a polycrystalline solid section. 9.6 - Hot Dip Coating is obtained by dipping the substrate into a molten metal.

10 - Explorations: beyond the Welder Physicists See Potential Dark Matter from the Sun The

Science of Monster Storms 45,000-Year-Old Man's Genome Sequenced Are U.S. Hospitals Prepared for the Next Ebola Case? Cheap Solar Power Becomes Employee Perk

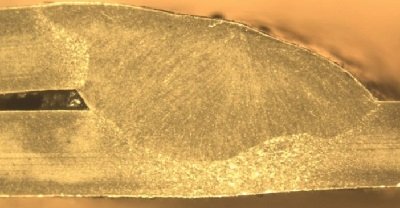

11 - Contributions: Activated TIG Welding A 2009 paper published by The Welding Institute (TWI) reports on research conducted to study the influence of specific fluxes applied on the metal surface to increase penetration and productivity of TIG Welding (GTAW). The article briefly reviews some of the most significant developments introduced along the years in the basic TIG process remarking that, while the weld bead penetration profile was improved, the productivity advantage remained marginal. Activated TIG (A-TIG) welding was researched with the purpose of studying the possibility of enhancing the productivity of this process. It consists in performing regular TIG welding on a metal surface covered with a thin coating of activating flux material. The flux effect appears to be the constricting of the arc, which increases the current density at the anode root and the arc force on the weld pool. The actual mechanism is still not fully understood. The industry however has been slow in adopting the process because of the additional operations required (flux application and slag residual removal), and because of the somewhat inferior surface finishing. TWI developed better flux products. The work intended to confirm the improved weld penetration depth and productivity for stainless steel tube materials. It was found that quality, reduced edge preparation and distortion, and improved productivity could make the A-TIG welding process more attractive than the conventional TIG process in tube welding. The article lists the specific advantages and the characteristics of the new flux. It also proposes theoretical mechanisms that would explain the favorable results obtained. Then the objectives of the research are outlined and the experimental program is described. The conclusions confirm the advantages inherent in the new method. No further comment is offered to explain why A-TIG is not widely adopted in the industry. Interested Readers are invited to read the original article. Investigation of the A-TIG mechanism and the productivity benefits in TIG welding

Conventional TIG and A-TIG welds in 29mm OD 1.6mm WT laser seam welded 304L tube

From the above TWI Investigation.

12 - Testimonials On Wed Oct 01 15:46:38 2014, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Reza Rashidi Reza Rashidi

On Sat Oct 11 21:57:35 2014, the following results were submitted from the "Form 5" on welding-advisers.com: Name: James Cope [...] Thank You so much!

13 - Correspondence: a few Comments I was reading recently an interesting book by Nassim Nicholas Taleb, called Antifragile: Things That Gain from Disorder. Among other very important things, the Author makes the point that useful developments were often achieved by simply tinkering with certain objects until some working contraption are successfully produced. That happened even if the original concept was somehow blurred or unclear or even not correct. I would like to ask my readers if they too think that the best achievements are often due to tinkering or trial and error, and if they have some successful outcome they would like to share.

14 - Bulletin Board 14.1 - International Conference on Mechanics and Civil Engineering (ICMCE 2014) 14.2 - International Symposium on Engineering Technology, Education and Management (ISETEM 2014) 14.3 - 2nd Arabia Essen Welding & Cutting

Watch - The Video: and also BUILT BY: Click on this Logo NOW! Copyright (©) 2014, by Elia E. Levi and

See you next time...

|

|||||||||||||

| Back to Back Issues Page |