|

Adhesive-bondingJoints without Welds.Solutions with Effective, Practical AdviceAdhesive-bonding is a joining process whereby materials are held together by the surface attachment of adhesives. It is similar to welding only in the function it performs, and as such it may provide an advantageous alternative to classic joining procedures in well defined applications. It is therefore not surprising to find a Chapter on this bonding method at page 333 of the

For similar reasons a short page on Adhesive-bonding is hereby included in this www.welding-advisers.com Site. Although different from Welding, Structural Adhesive bonding, called also adhesive joining, adhesion welding or joints without weld, has increasing importance for attaching metals to themselves and to ceramics or composite materials. It is one more tool in store for those special occasions when other methods fail to meet requirements. Adhesive-bonding provides advantages for the sheet metal industry, including reduced operator skill and less postweld finishing. It can result in higher manufacturing efficiency, more extensive stress distribution, and cleaner product surfaces. When looking for the use of Adhesive-bonding as a joining solution, and especially if redesigning a joint originally intended for a different joining process, one should keep in mind the advantages and the limitations of structural adhesives, to be checked against the environmental conditions prevailing during the service life of the specific application. If you did not yet find what you need, why not typing your question in the following Search Box?

Limitations of Adhesive-bonding:

Note: A short Glossary on Terms and Definitions pertaining to Adhesive-bonding was included in Practical Welding Letter of March 2004. For seeing this PWL click on PWL#007. An Article on Joining Composites to Metals was published in the Issue 25 of September 2005 of Practical Welding Letter. To read the article Click on PWL#025. An Article on A new metallic glue was published (11) in Issue 150 of Practical Welding Letter for February 2016. An Article on Testing Automotive Composites was published (3) in Issue 152 of Practical Welding Letter for April 2016.

Design for Adhesive-bonding Adhesives selected primarily for their load carrying capacity are designated structural adhesives. A new page was published to include an enlarged chapter devoted to Adhesive-bonding design and a thorough presentation on properties. Adhesives Adhesives are liquids or pastes that must be converted to a solid state. This change is commonly achieved through polymerization or curing. Adhesives have limited storage life, beyond which they cannot be used. They must be stored in accordance with manufacturers' recommendations. Adhesives are characterized by chemical type and by the following properties: There are many curing processes available, and many adhesive systems use more than one; therefore each process should be considered individually. Curing systems: UV curable and radiation curable adhesives use ultraviolet light or other radiation sources to initiate curing, which allow a permanent bond without heating. Light-cure adhesives contain photoinitiators that absorb light energy to begin polymerization. Upon exposure to the appropriate light source, the adhesive cures fully in less than a minute. Some thermoplastics, including many grades of polycarbonate, contain additives that block UV radiation and cannot be used with UV-cure adhesives. The new visible light-cure adhesives have solved this problem. Heat Curing: a relatively simple process easily controlled by maintaining consistent cure times and temperature. The process usually aids adhesion and forms thoroughly cross-linked polymer networks. Phenolic, melamine and urea formaldehyde resins are thermosetting adhesives that offer strong bonds and good resistance to relatively high temperatures, harden and cure by a chemical reaction at elevated temperature. Thermoplastic adhesives soften repeatedly with temperature and harden when cooling. They can be repeatedly softened by heat and hardened or set by cooling, which allows parts to be removed or repositioned during assembly. Moisture curing in certain reactive systems: polymerization starts under the influence of ambient moisture. Curing by exclusion of oxygen is that occurring in anaerobic adhesives, after the application excludes the contact with air. Cross linking polymerization occurs in two-part adhesive systems that are made up of a base polymer resin and a catalyst. When mixed, the adhesive starts to polymerize, forming a thermoset polymer, assisted or not by applied external heat. Types of adhesives The most important adhesives for structural and engineering applications are: anaerobics, epoxies, reactive acrylics, polyurethanes, reactive hot melt polyurethanes, cyanoacrylates and silicone based. There are also specialty adhesives available for extreme temperature conditions. Anaerobics are also classified as chemically reactive one-component (liquid or paste) adhesives, that remain liquid when exposed to air. They cure by polymerization upon elimination of oxygen in air. They are useful for coaxial joints and gasketing, for locking and sealing threaded assemblies, for retaining bearings and bushings, with good resistance to environment.

Epoxy adhesives are chemical compounds used for joining components. Curing (polymerization) develops under heat and pressure, or for two parts (resin and catalyst) after mixing, at room temperature, but may be hastened by heat. They present strength and durability for a vast range of applications. They have good resistance to ambient factors. Acrylic adhesives are known for their excellent environmental resistance and fast-setting times when compared to other resin systems. Some two component (two-part) systems do not require careful mixing, such as modified acrylics, in which accelerator is applied to one surface, adhesive to a second and the surfaces are joined. They present good environmental resistance. Polyurethane adhesives, in either one or two parts, provide excellent flexibility, impact resistance, durability, good gap filling and sealing properties, best when strength requirements are low, with ability to foam. They have fair to good resistance to ambient factors. Hot melt polyurethane reactive adhesives are solid at room temperature. They melt at relatively low temperature and their viscosity while molten can be designed according to applications. They cure to termosetting condition that resists further melting. Cured adhesive (from ambient moisture, without heat) have excellent temperature and environmental resistance. Cyanoacrylates, also known as instant adhesives, are one-part liquid systems that harden rapidly at room temperature by the action of residual moisture when pressed into thin films to form strong bonds between substrates. They are solvent free and resistant to many environmental factors, with less odor and more flexibility and are suitable for bonding metal, plastics and rubber.

Silicone adhesives and silicone sealants have a high degree of flexibility and very high temperature resistance. Silicones are One or two part viscous liquids or pastes. They are used as adhesive sealants for welded joints, as silicone rubber gaskets and heat resistant seals, and as coatings for moisture and corrosion resistance. Adhesive Selection The selection of an adhesive for Adhesive-bonding depends on application requirements, processing considerations and environmental conditions. Selecting the most suitable adhesive is a critical factor that contributes to the success of the application. One should start by specifying service requirements of joints, such as operating forces, temperature, and design life. Then one should consider the suitability of candidate adhesives to the type of substrates to be joined. Process consideration should be taken into account to verify feasibility of application and absence of operations susceptible of impairing the base material properties. One should consider Quality provisions, by establishing strict procedures to be followed by all involved. Suitable periodic tests of test pieces should be established as well as types of Non Destructive Testing to be performed on finished parts. The most suitable candidates should be listed in a comparison table of properties and costs for evaluation. Finally a few prototype joints using a few of the most promising candidate adhesives should be prepared by Adhesive-bonding for actual testing and evaluation. Surface preparation and strict adherence to proven application procedures, including ambient temperature and humidity conditions, is essential to the success of the applications. Personnel should be trained in use of adhesives because of health and safety concerns variably applicable to different systems. In particular some materials may be toxic, irritant, or produce respiratory and skin or eye problems if not dealt with cautiously.

WELDING RESOURCES

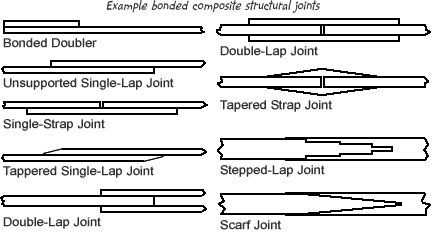

See the following examples of Adhesive-Bonded-Joints:

[From http://www.vircon-composites.com/2_3_2.asp]

Scorpion [From https://www.welding-advisers.com/nature.html]

Site Map SAFETY Adhesive Joint Design. Additional Processes

And get a free Download, right to your computer, of our Book, Practical HARDNESS TESTING Made Simple, in pdf format. To get it, just Subscribe.

POWERED BY: Click on this Logo NOW! Copyright (c) 2003-2012, 2013, 2014, 2015, 2016, 2017 Adhesive-bonding: an alternative joining process displaying certain advantages and a few limitations. Read all about this...

|